CPFormplast and Sulapac Partner to Redefine Sustainable Thermoformed Packaging

Sustainable Biobased material for thermoforming!

We are thrilled to announce a strategic collaboration between CP Formplast — a leader in thermoformed packaging — and Sulapac — the Finnish material innovator on a mission to replace conventional plastic.

With this partnership we combine manufacturing know-how with next-generation materials to deliver sustainable packaging solutions.

Why CPFormplast?

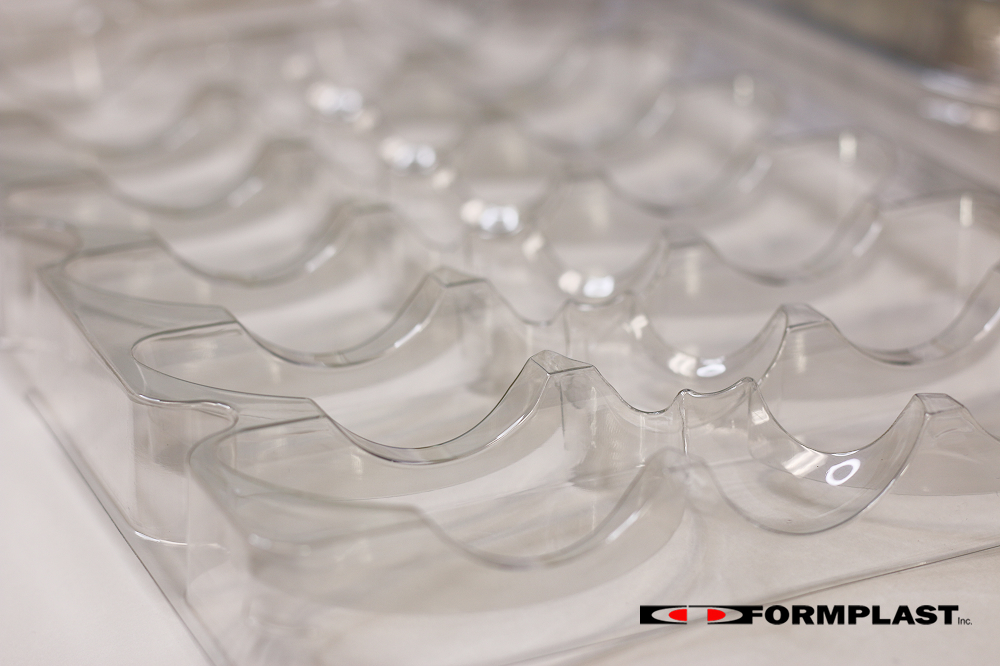

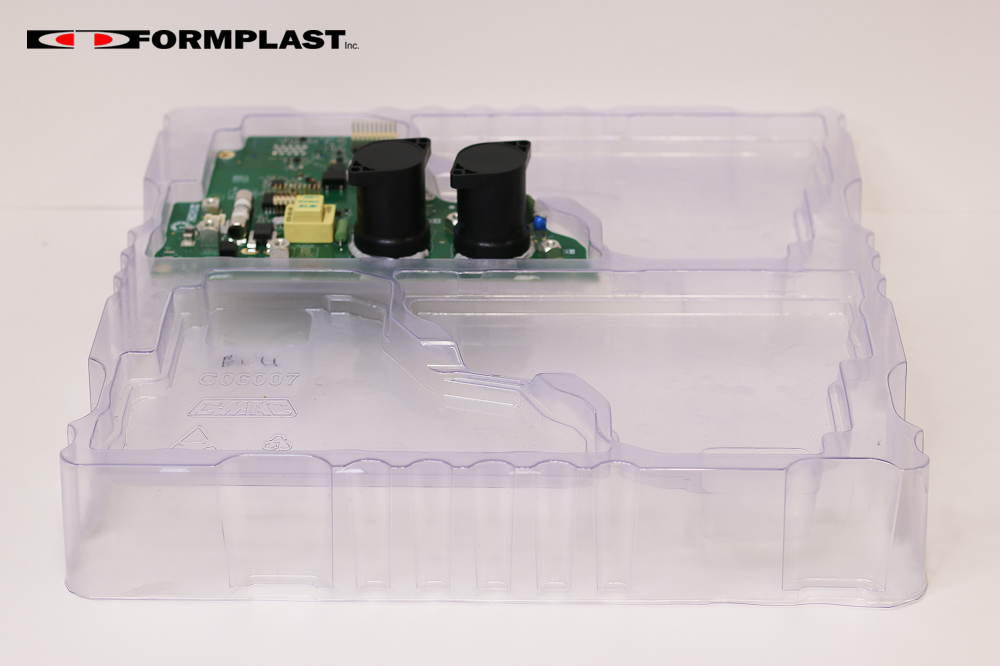

Founded in 1981, CP Formplast has decades of experience designing and manufacturing custom thermoformed packaging for industries ranging from food and cosmetics to electronics and medical.

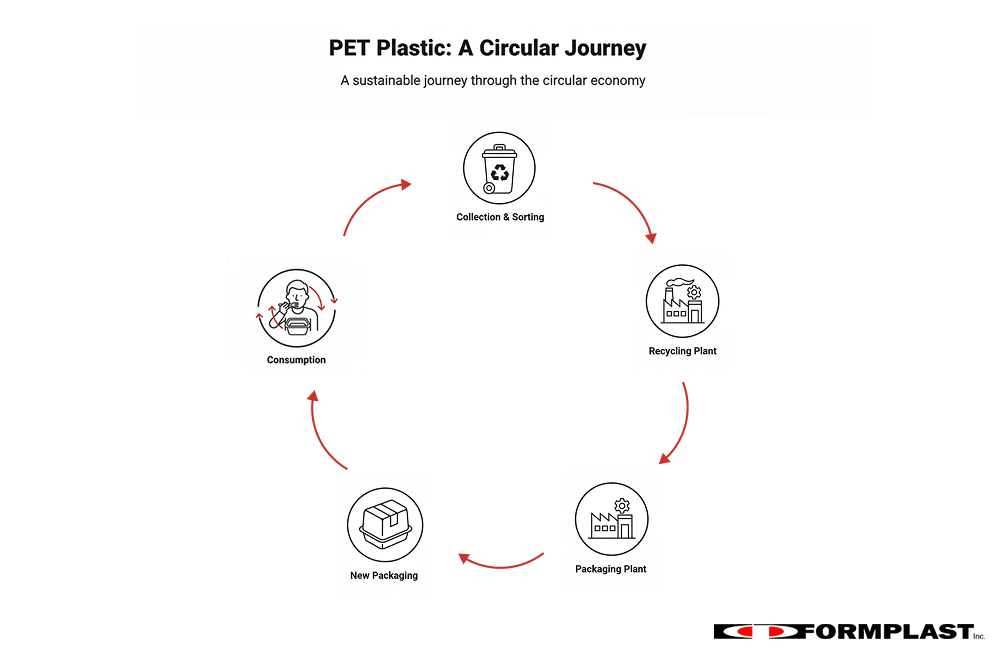

Importantly, CP Formplast has embedded sustainability into its operations. Their mission emphasizes recyclable and recycled-content materials.

Committed to the 3Rs — Reduce, Reuse, Recycle: CP Formplast designs packaging with circular economy principles in mind, using recycled and recyclable materials, optimizing energy use, and minimizing waste and water consumption.

Why Sulapac?

Sulapac is a breakthrough in materials science: its proprietary biocomposite uses sustainably-sourced wood side-streams plus plant-based binders, creating a material that biodegrades without leaving permanent microplastics behind.

Further, Sulapac’s materials are drop-in compatible with existing machinery — meaning packaging converters don’t need to completely rebuild their lines to adopt them.

Sulapac products offer a premium quality and beautiful natural look, suitable for high-end and functional applications.

Applications & Industries

Together, the companies are targeting several key markets:

Food packaging: Lightweight trays or clamshells made from a bio-based, compostable grade of Sulapac.

- Protective packaging: Thermoformed packaging for electronics or health care where material performance cannot be compromised.

Cosmetics & luxury goods: Trays, inserts and displays that deliver premium look and feel with a lower environmental footprint.

What this means for brands

For brands considering a switch, this collaboration offers:

Access to packaging solutions that tick sustainability credentials and aesthetic/functional requirements.

A smoother transition path: using established thermoforming practices (via CP Formplast) with new material technology (via Sulapac).

A story worth telling: marrying craftsmanship of custom packaging with genuine material innovation.

In short: you don’t have to compromise on look, feel or performance to be more responsible.

Looking Ahead

As this partnership matures, we anticipate rollout of new product lines and materials optimized for thermoforming, with further reductions in carbon footprint and waste.

Also, broader adoption means greater volumes, which drives cost-efficiencies — a key lever for this kind of innovation to become mainstream.

It’s not about a niche ‘eco’ product anymore — it’s about the next normal in packaging.

Easy to process material with natural look and feel

Sulapac Flow 1.7 is made from wood industry side streams and biodegradable biopolymers with 72% bio-based content.It’s safe for people and the planet, industrially compostable, and compliant with EU and FDA food contact standards.

The material offers premium detail and consistency, can be mechanically recycled, and has a cradle-to-gate carbon footprint of 1.15 kg CO₂ eq/kg (biogenic carbon included)

Join us on the journey

Whether you’re a brand looking to elevate your packaging, a designer curious about new materials, or a supply chain stakeholder ready to think differently — this partnership opens doors.

Get in touch with CP Formplast to explore how your next packaging project can be greener without compromise.

1 Relative biodegradation of 76% in 420 days in simulated marine environment test (ASTM D6691, 86°F / 30°C) using natural sea water. Not considered biodegradable in California.

2 Ecotoxicity and threshold values for heavy metals tested according to EN 13432.

Tested for per-and polyfluoroalkyl substances (PFAS) by an independent laboratory (ISO/IEC 17025 certified) based on CEN/TS 15968 test method; No PFAS compounds were detected.

In addition, Sulapac Flow has been analyzed in the Daphnia magna plankton toxicity test (according to OPPTS 850.1010 & OECD 202): test series showed that the degradation products of Sulapac Flow are non-toxic, and therefore, do not have any harmful effect on the plankton in the marine ecosystem.

3 The compostability has been tested up to the thickness of 910 μm according to BPI (ASTM D6400) and Seedling (EN 13423).

4 Restrictions and specifications of use apply, please refer to relevant Declaration of Compliance for further information.